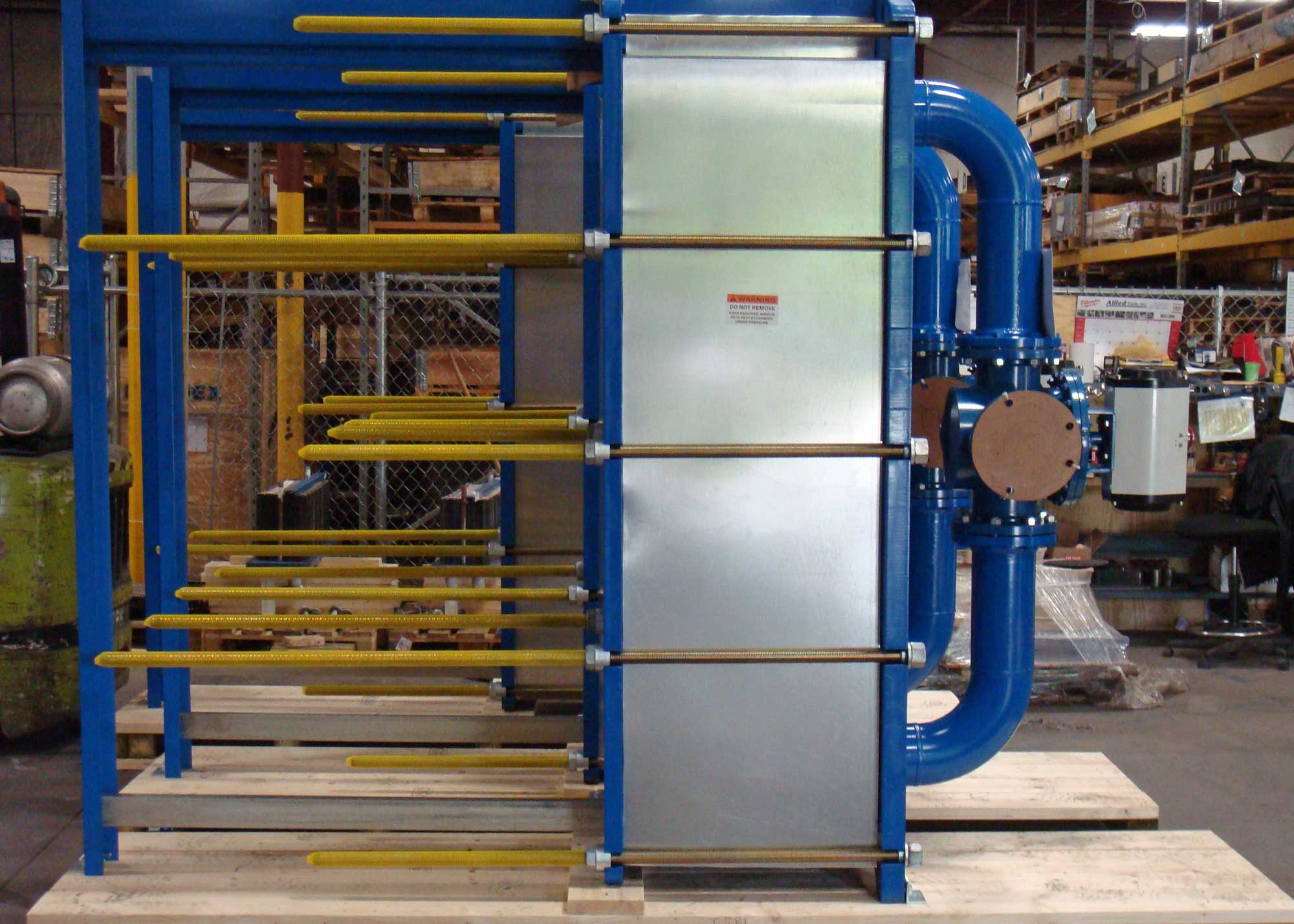

Gasketed Plate & Frame Heat Exchangers

The plate & frame heat exchanger is widely considered the most efficient type of heat exchange equipment available today. Plate heat exchangers are often the lowest cost solution to heat transfer problems in the industrial and commercial HVAC markets.

Key Advantages & Benefits

Compact Design Ideal for Tight Spaces

Minimal footprint enables installation at locations where available space is at a premium.

High Efficiency at its Best

HIgh heat transfer coefficients and close temperature approaches are achieved economically for maximum energy conservation.

Low Fouling & Easy Maintenance

Intense turbulence and shear rates induced by our MODUFLEX™ plate designs provide for superior thermal performance and minimized risk of fouling. Plate heat exchangers can be easily opened so that all heat transfer surfaces are accessible for mechanical cleaning and/or pressure washing.

Plate Concepts can also supply plate heat exchangers with additional accessories such as strainers, Clean-in-Place (CIP) systems, and Diverter Valves for Back-flushing to prevent fouling.

Flexible Design / Expandable

The all bolted, modular construction of the plate heat exchanger makes it easily expandable for increased heat load requirements and capacity upgrades. The exchanger can be modified for another service by simply opening the plate pack and installing additional plates in the frame.

Gasketed Plates: A Complete Range

Based on our MODU-FLEX™ series of plates, Plate Concepts offers an extensive range of Plate & Frame Heat Exchanger innovations and design capabilities to meet your heat transfer needs.

Port Diameter Sizes

- 1" to 20" (5 - 15,000 GPM)

Materials of Construction

- 304 / 316 SS, Titanium, 254 SMO, or Hastelloy™

Heat Transfer Area

- Up to 15,000 sq feet in a single frame

Design Pressures

- 150 to 450 PSIG

Gasket Materials

- Nitrile (NBR), EPDM or Viton

Design Standards

- ASME Code Section VIII, Div. 1 Stamped

- National Board registered

- ARI Certified to Standard 400

Special Plate Designs

- Free-Flow (Wide-Gap) Plates

- Welded Cassette Plates

- Double Wall Plates

- Brazed Plate Heat Exchangers